H2 sensor system for Li-ion battery monitoring for automotive applications.

Lithium-ion cells can pose major hazards. Mechanical damage, water ingress, overcharging or deep discharging (see bottom page) can result in the build up of flammable gase. In worst-case scenario a fire or explosion can ocour.

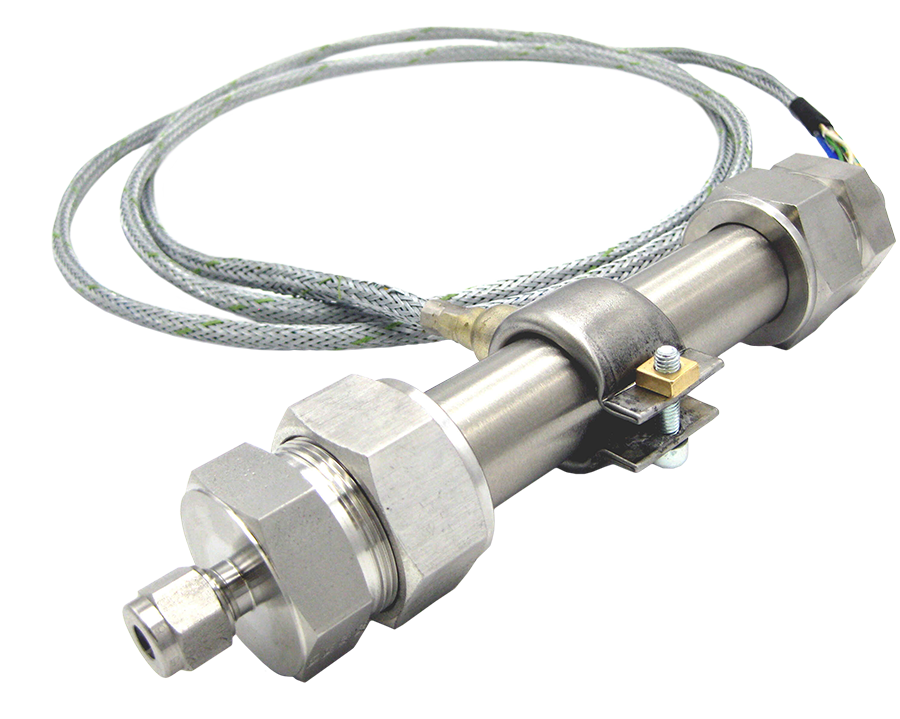

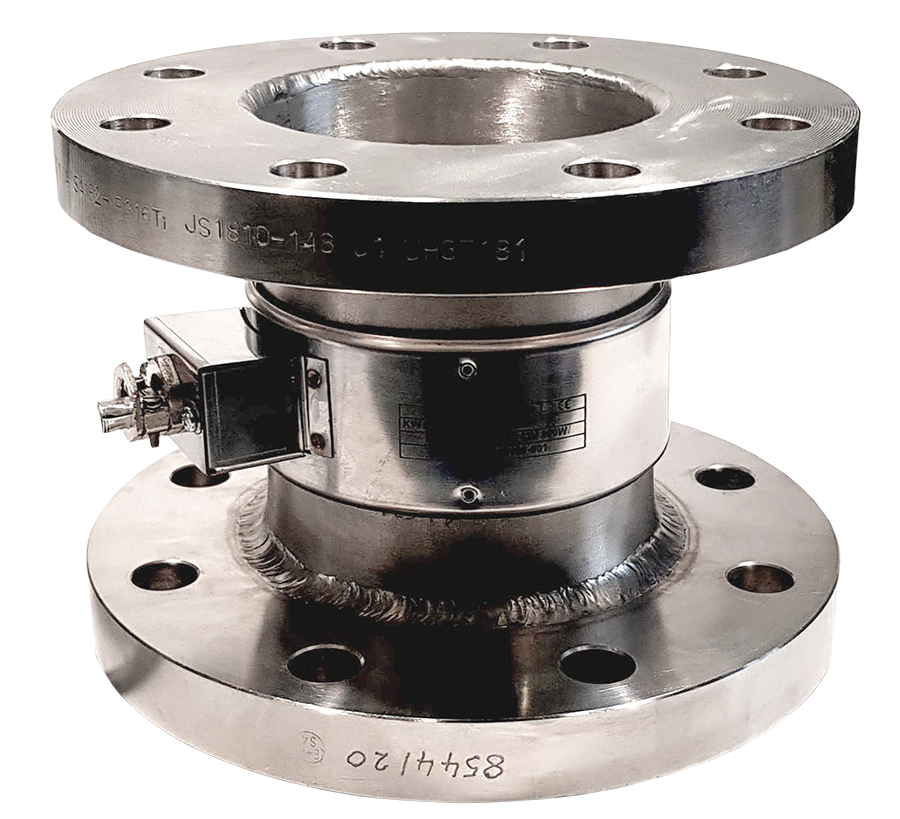

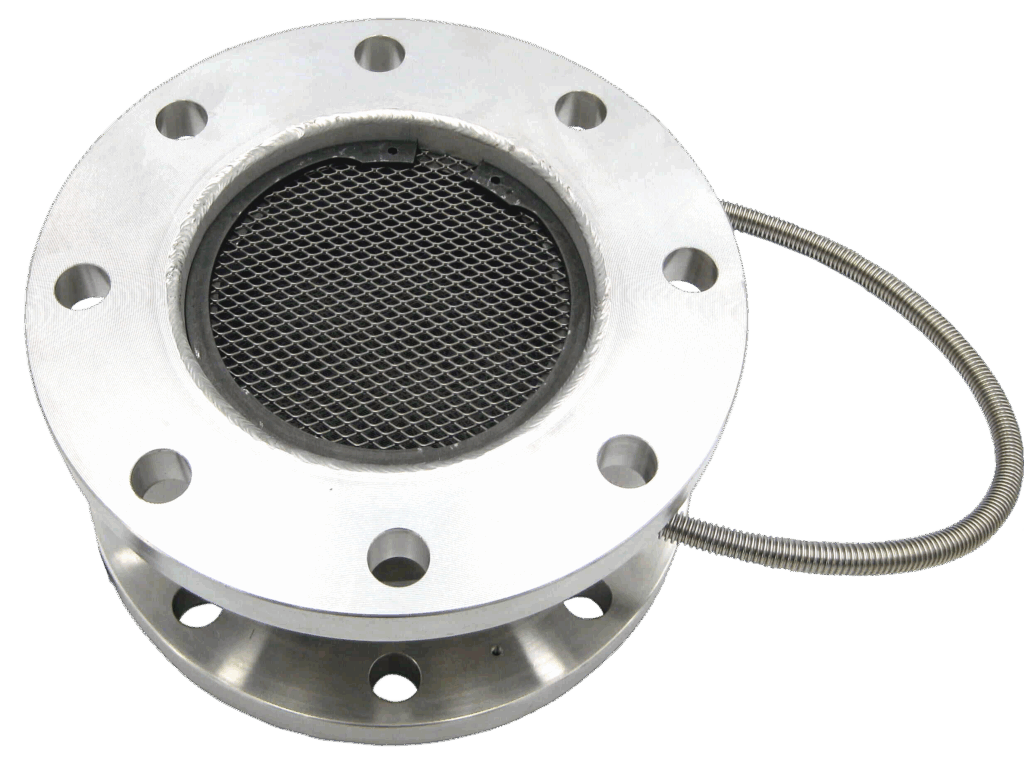

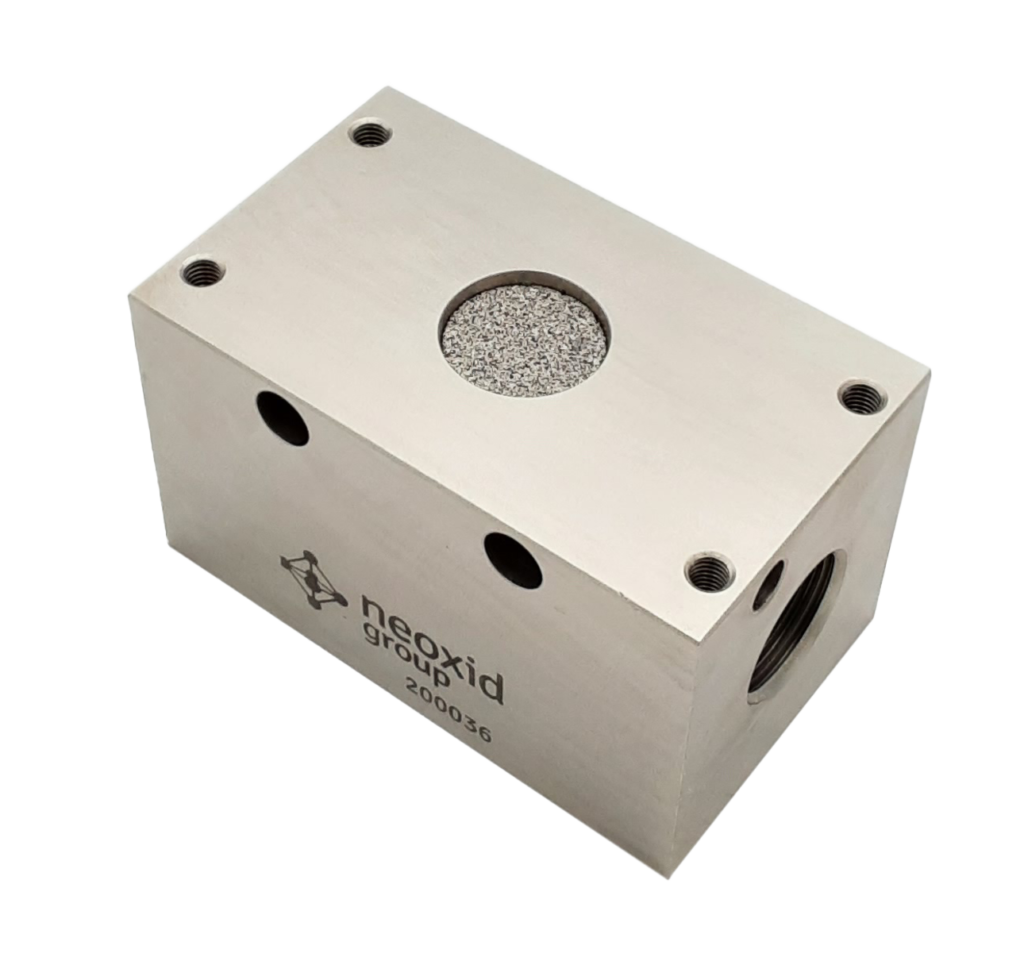

The NEO1002 sensor system can monitor a battery/high-voltage storage system HVS and detects the hydrogen concentration, reducing and oxidizing gases, the gas pressure (pressure increase when gas escapes), water formation and also the battery temperature (“thermal runaway”) directly in the .

Most important features:

- Measuring range: 0-2 vol.-% H2 (1⁄2 LEL)

- Carrier gases Air

- Measuring signal independent of ambient temperature and pressure

- Detection of thermal runaway, pressure increase and reducing gases in a battery/rechargeable battery

- Temperature measuring range: -40 to 85 °C

- Pressure range: 0.6 – 2 bar absolute

- Humidity: 0 – 90 % r.h. (non-condensing)

- Response time: t90< 3 s

- Recovery time: t10< 3 s

- Signal: CAN 2.0 A/B with 125/250/500/1000 kbps